HOT-FILL DOS 3

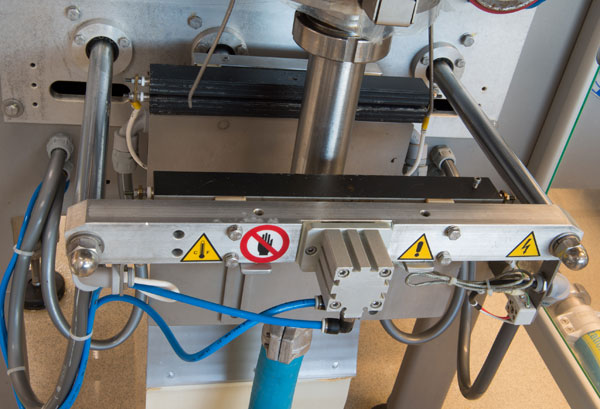

Dosing of hot foods is usually associated with a number of occupational health risks, but these are minimized with a fully automatic dosing system. The automation ensures that your employees do not come into direct contact with the 90° hot product. The automatic bag machine seals the bags after filling. The need for long distance lifts is also reduced, as the ready-packed meals are transported from the filling to the employee via a small conveyor belt.

HOT-FILL DOS 3 ensures uniform portion sizes. The amount to be dosed into the bags is determined via a touch screen control panel. This also determines how quickly the product should be dosed, so that the workflow can be arranged accordingly.

The fully automatic HOT-FILL DOS 3 can suck directly from the kitchen’s kettles, and is equipped with a temperature alarm, so the portioning always occurs at the right temperature.

HOT-FILL DOS 3 ensures a safe and efficient procedure for dosing food into bags

The process

The suction hose is fittet to the kettle

The desired amount per bag is entered on the touch screen operation

Press start

The bags are automatically made by the bag machine, which is fed from a foil roll on the machine

HOT-FILL DOS 3 draws from the pot and doses the desired amount into the bags

Once production is completed, the CIP cleaning system is connected by fitting the CIP hose onto the bag machine

The CIP cleaning system cleans all internal parts such as hoses, pipes, valves and pump

The cleaning program is fully automatic and dispenses cleaning and disinfecting agents itself

Technical specifications

HOT-FILL/CIP for bag-packing unit

Item No: 5200

Power Supply: CEE plug, 32 A fuse, 400 Volt

Type B RCD 300 mA

Cold water: 3/4”, 2½” bar

Warm water: 3/4”, 2½” bar

Drain: 100 mm in diameter

Bag-packing unit

Item No: 5200

Power Supply: CEE plug, 16 A fuse, 400 Volt

Type B RCD 300 mA

Air Supply: 7 bar, 400 l per min.

Drain: 100 mm in diameter

Product highlights

- Made of stainless steel in a cleaning-friendly design

- Can dose purees, soups, sauces etc.

- Doses directly from pot to HOT-FILL bags

- Fully automatic cleaning program

- Touch screen operation

- Temperature alarm with data logging. Data output – via USB connection. Read amount, time, and temperature

- Doses in 1 kg to 4 kg HOT-FILL bags

Accessories

-

HOT-FILL DOS 3 is supplied with pulse dosing

-

It is possible to opt for weight dosing